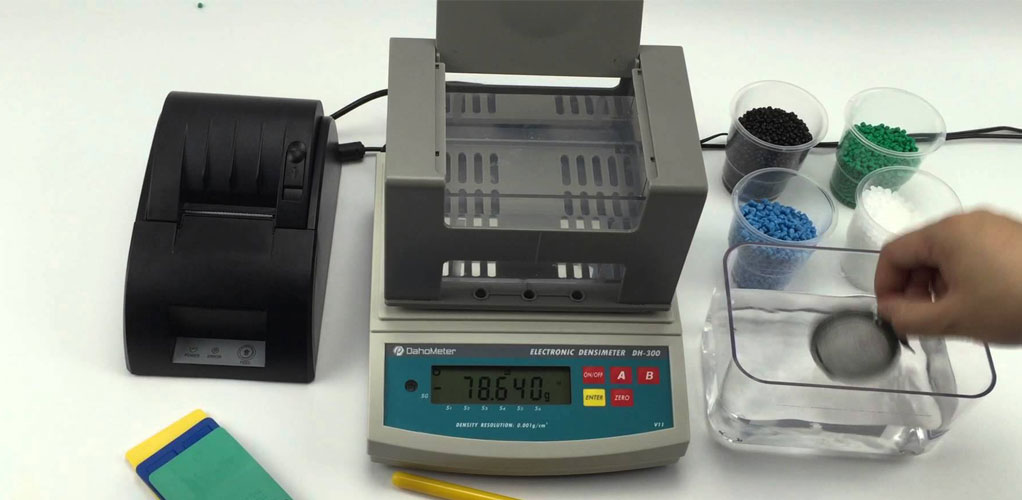

Testing & Inspection Facility:

Navana Engineering Ltd has a well-equipped Quality control laboratory with all modern for Chemical, Physical and Mechanical Testing properties of basic raw material, Pipe, Socket and Galvanizing.

Quality control is the watchword and we believe that quality assurance begins at the raw materials stage itself. There is a reason why we source raw materials for plastic pipes from none other than prime producers from home and abroad. Materials are subjected to visual inspection and dimensional checks. Chemical composition and mechanical property are also tested to ascertain its conformity to relevant standards. The materials get approved by National and International Inspecting Authorities like ISO, WRAS, DIN, BSTI, BUET and RUET and many more assuring our customers quality and 100 per cent satisfaction in every aspect.